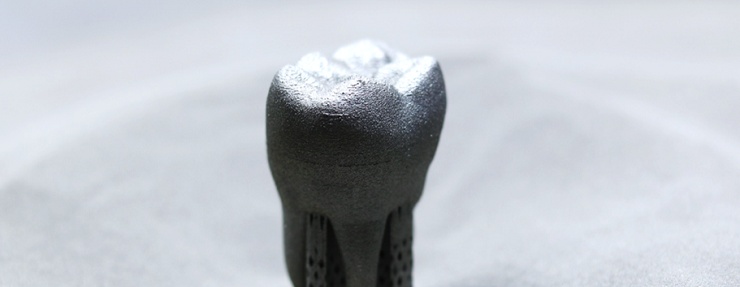

Medidur - The material for additive manufacturing in medical technology

Whether implants, dental prostheses, orthoses or prostheses - additive manufacturing is essential for medical technology. The newly developed material Medidur is an austenitic, patent-pending steel powder for additive manufacturing. The use of manganese eliminates the need for nickel. The material is non-magnetic, corrosion resistant and offers high strength, which is particularly advantageous for medical applications. In addition, employees and patients are not exposed to nickel.

The advantages of Medidur® at a glance

- Good processability using LPBF. The typical processing parameters of 316L can be used.

- Medidur® is manufactured without the alloying element nickel. As a result, the safety requirements during processing of the powder are significantly reduced.

- By eliminating the element nickel, Medidur® can be used for medical purposes.

- Significantly increased yield strength, tensile strength and hardness compared to typical austenitic steels (e.g. 316L).

- A high PREN (Pitting Resistance Equivalent Number) rating of 36 (316L = 28) and therefore very good corrosion resistance.

- High tendency to work hardening.

- The properties of Medidur® in combination with our production according to DIN EN ISO 13485 (quality management for medical products) make Medidur the first choice for applications in medical technology.