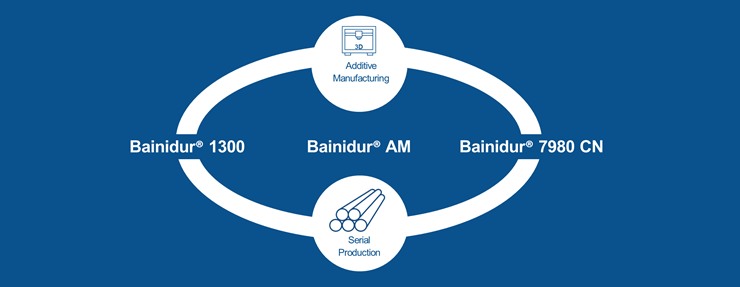

Bainidur – From Additive Manufacturing to serial production

DEW meet this demand with the established special steels Bainidur 1300 and Bainidur 7980 CN. The new bainitic steels do not only expand the large-scale production via electric arc furnace but also with Bainidur AM (= Additive Manufacturing) the metal powder portfolio.

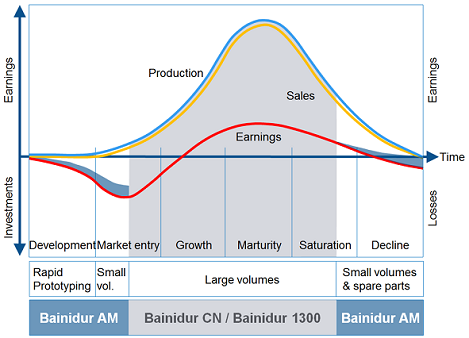

There are currently only a few low- and medium-alloy steels available on the market which can be processed by Additive Manufacturing. Bainidur AM, on the other hand, meets this need because it allows initial samples to be printed quickly and efficiently, which also exhibits the later component properties. Heat treatment and thermochemical surface treatments can be tested and optimized with the same material as in the serial production.

Even spare parts, when the forging dies no longer exist, can be produced by Additive Manufacturing with the same properties as the original. This is supported by its good transformation behavior into the bainite structure. This makes the material easy to handle during powder production and printing.

Bainidur 7980 CN

Bainidur 7980 CN is specially designed for case hardening and carbo-nitriding. The steel is a low-alloyed steel with a bainitic structure at ambient temperature. Bainidur 7980 CN is an optimum solution for a lot of applications regarding economic, mechanical properties and process stability. Fields of applications are gears especially for e-mobility with high torque or large gears in wind mills.

Bainidur 1300

Bainidur 1300 is designed especially for robust processes with low dependence of mechanical properties on size and a low risk of cracks or distortion during cooling. Bainidur 1300 is an optimum solution for a lot of forging applications regarding economic efficiency, mechanical properties and process stability.